All the info you need,

gathered effortlessly

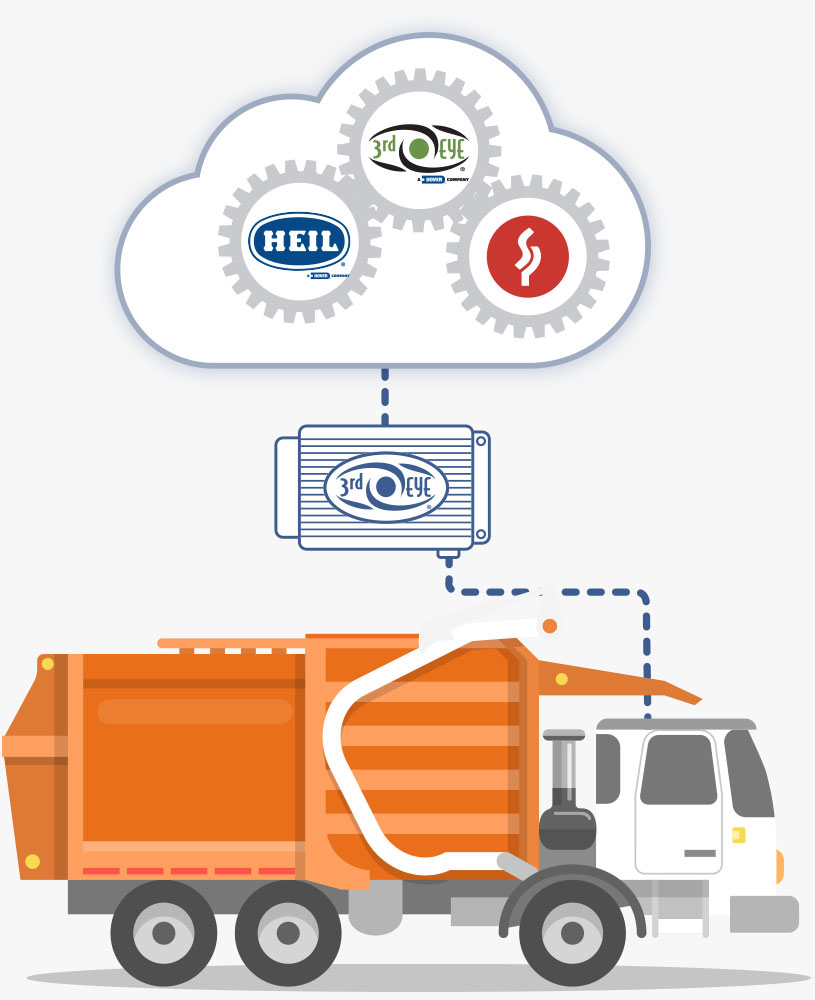

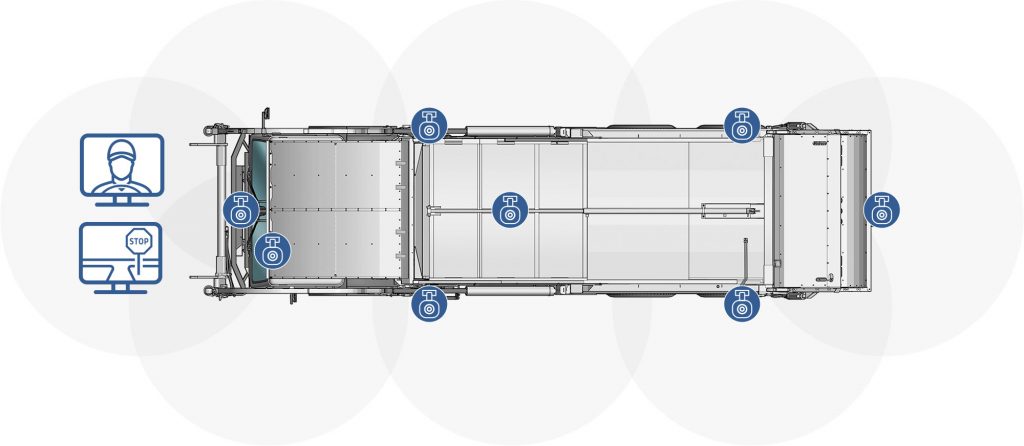

It all starts with the refuse collection vehicle and 3rd Eye. The 3rd Eye digital system can support up to eight cameras to provide fleet owners 360-degree visibility, including the driver and what the driver sees. In addition, both chassis and body data are being transmitted on the J-1939 network through the 3rd Eye gateway in the cab. From here – everything is broadcast in real time to the Cloud – where it is then compiled and converted into actionable information, which fleet owners can use to make better decisions, faster.

It’s important to note that all route and vehicle data collection is passive so that the driver can focus on operating the vehicle safely without having to shift focus to either take images or input route collection information.

Up to eight 3rd Eye® cameras provide 360° of visibility,

including the driver and what the driver sees.

3rd Eye Digital allows fleet owners to see both what the driver sees…and doesn’t see in real time. This information allows fleet owners to assess route conditions, customer service events, and driver behavior. All of this is passively uploaded to the cloud where the information is ported to Soft-Pak for customer billing. Driver behavioral events are ported to the 3rd Eye review team to alert fleet owners of possible coaching events – as well as post-event fault analysis.

Safety

With 3rd Eye, safety video – captured in real time from up to eight camera inputs, is ported to the 3rd Eye review team to help improve driver behavior, as well as provide fleet owners with a view of what the driver sees… and what doesn’t see. Video findings can be used for positive coaching events, as well as post-accident fault mitigation.

Vehicle Analytics

Engine data is run through analytics for predictive maintenance where open work orders can be automatically sent to a fleet’s maintenance system based on vehicle fault codes – via the 3rd Eye Optim-Eyes™ module.

POSITIVE SERVICE VERIFICATION

Positive Service Verification images, collected passively, are sent to Soft-Pak for customer service, billing, and reporting. Fleets can access pictures or videos immediately when a customer has been serviced, when the container is overloaded, not out, or when it is blocked, and can provide customers with an updated service schedule if there are delays on the route.

MAP-PAK® & MOBILE-PAK™

Soft-Pak, Mobile-Pak, and Map-Pack software provides turn-by-turn route guidance – real-time productivity status, and communication between dispatch and the operator for immediate workload revisions via their in-cab tablet. Access pictures or videos immediately when a customer has been serviced, and provide customers with an updated service schedule if there are delays on the route. This dramatically increases route productivity and end-user satisfaction.

Generate revenue. Reduce costs. Automate Processes.

With over 1-million data points generated per truck per day – along with asset positional information, 3rd Eye provides revenue generating solutions, such as overloaded containers, and contamination recognition, as well as cost-reduction solutions, such as additional excise tax recovery, identifying “not outs”, or blocked containers. 3rd Eye also helps fleets automate processes, such as IFTA reporting and integrating engine hours and miles to our customer’s Maintenance ERP systems. All of this is possible right now to help customers make better decisions, faster.

Generate revenue.

Identify Recycling Contamination and Overloaded Containers.

Reduce cost.

Excise Tax Recovery, Identify “not outs” or blocked containers.

Automate processes.

IFTA Reporting, Integrate Engines Hrs. and Miles to Maintenance MRP systems.

Seamless Integration

The power of the Soft-Pak back office systems – along with our Mobile-Pak in-cab computing tablet, allows us to meld perfectly with Heil and 3rd Eye to produce a rich stream of data that represents virtually every aspect of a fleet’s asset during a workday. Fleet owners can access this passively collected data through our industry leading interface – to generate customer billing, track landfill weight tickets via our Scale-Pak® software, optimize route productivity via our Map-Pak® tablet-based turn-by-turn routing software – even optimize their roll-off routes. In short, Collected Connections makes it a lot easier for fleets to improve services levels and grow closer to their customers.